Optimized metal casting solidification modeling

What is OPTICast?

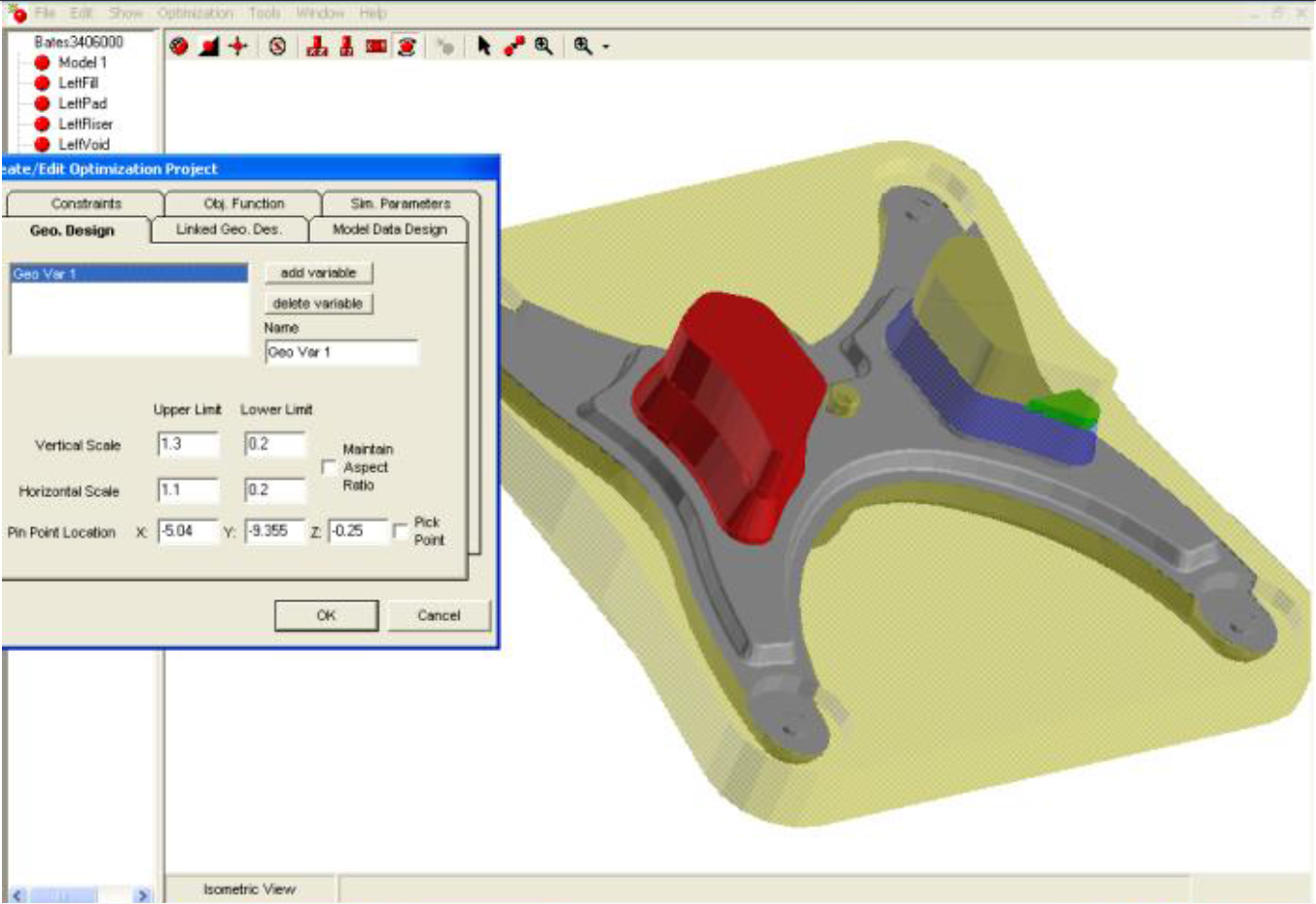

OPTICast is an optimization software product that works in conjunction with the SOLIDCast solidification modeling system. Most solidification modeling systems require the engineer to create a design, run a simulation, review the results, and then make a decision about how to modify the design to achieve a good casting. This can take several design iterations to get to the end result. OPTICast allows the foundry engineer to start with an initial design for a casting, with gating and risering, as a 3D model in the SOLIDCast modeling system.

Design Variables

With OPTICast, users can vary a multitude of elements in their castings, such as the height and diameter of a riser, the metal pouring temperature, the preheat temperature of an investment shell, or even the size of a gate or riser contact.

Constraints

OPTICast can be used to determine whether a particular design is acceptable. For example, a minimum acceptable yield percentage, or a maximum acceptable level of macroporosity. Many constraints can be used in a single optimization run.

The Objective Function

Users can set the Objective Function to focus on specific casting issues, such as maximizng the yield, minimizing shrinkage or minimizing solidification time. You can have only one objective per run.

Once these elements are identified, the user may launch the Optimization Run. This consists of a series of simulations in which the design conditions are varied under the control of OPTICast, model changes are made and simulation results are evaluated, all completely automatically, until the desired result is achieved. Using OPTICast, an engineer can start with an initial design and allow the computer to do the work of modifying the design and running simulations to achieve an optimum result.

Now, for the first time, the technology of automated design is brought to the foundry in the form of a practical and easy-to-use design tool. OPTICast can help you to improve your yield and your quality to an optimum point, while freeing design engineers from the repetitive task of trialand-error design.