The practical simulation solution from Finite Solutions Inc

Why do so many companies and schools worldwide use SOLIDCast™? BECAUSE IT WORKS!!

- Site License: Run on all your computers at no extra cost.

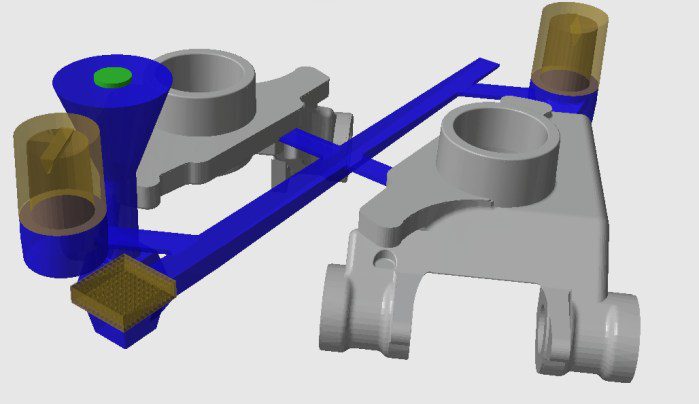

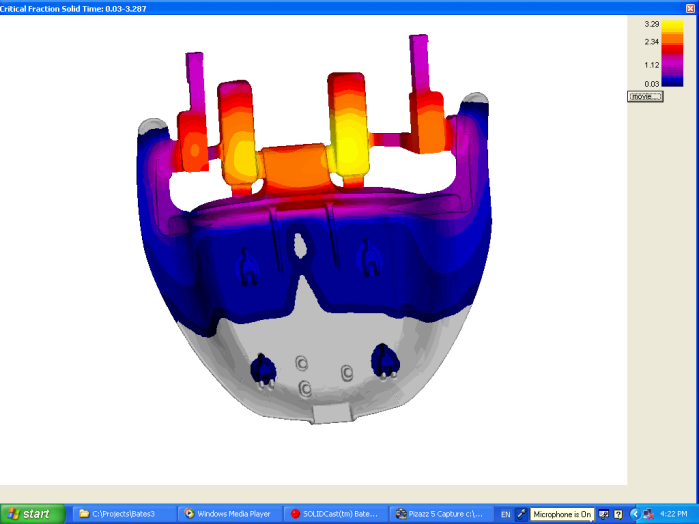

- Rigging Design Wizards: Simulation helps you design effective gating and risering.

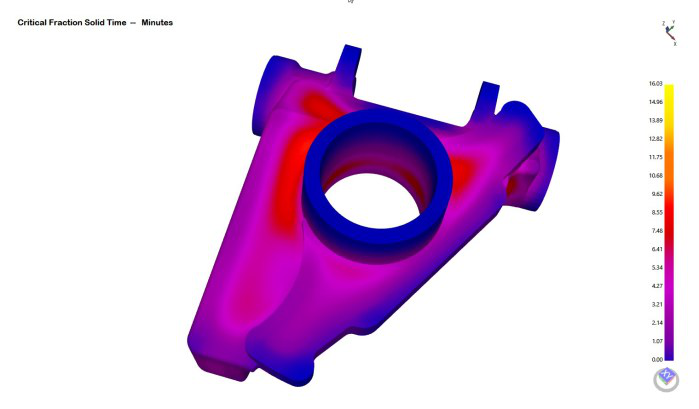

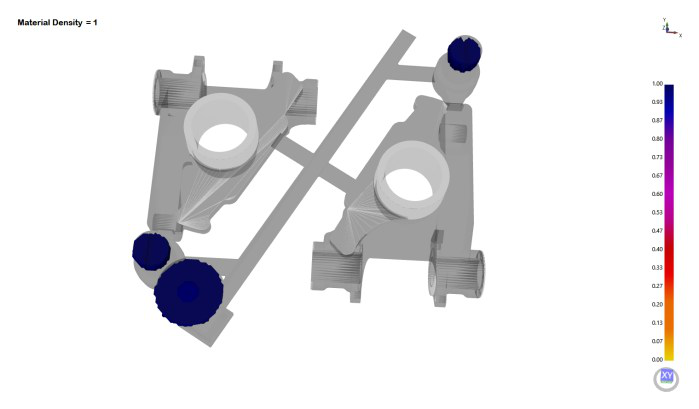

- Thermal & Volumetric Analysis: Simultaneously calculates changes for the most accurate shrinkage results.

- Video Training: Over 15 hours of video-based training included to get users up to speed immediately.

- Process Automation: Fully automate casting process optimization within SOLIDCast.

- Multi-Core Speed: Full simulations in minutes on standard, off-the-shelf PCs.

Sand Casting

SOLIDCast easily simulates the sand casting process. You can create molds automatically. Chills or sleeves? No problem. Combined thermal and volumetric calculations improve simulation accuracy. You can even predict the expansion phase in gray and ductile irons.

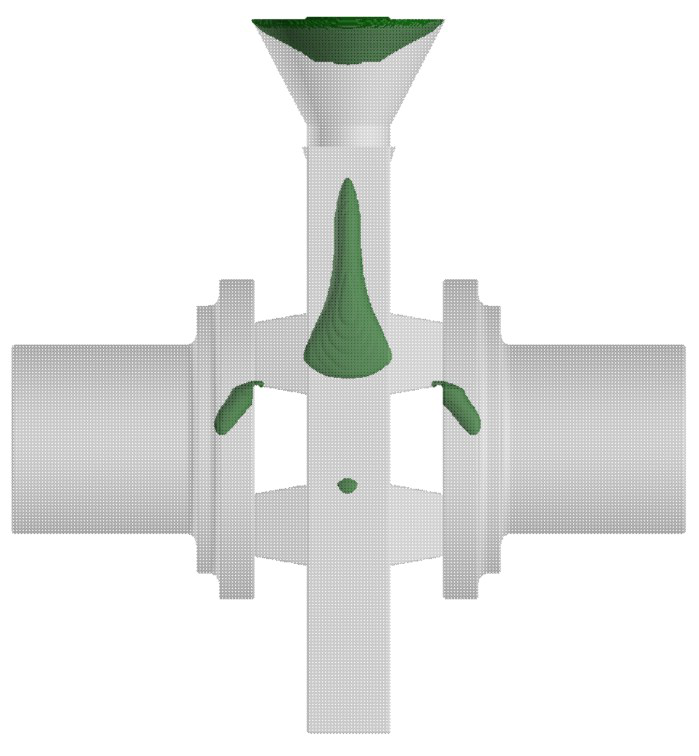

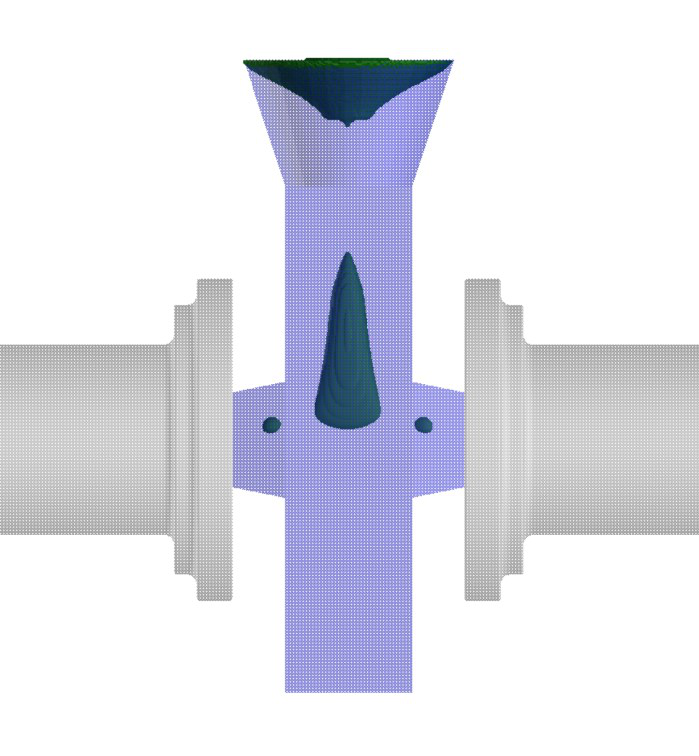

Investment Casting

SOLIDCast easily simulates the investment casting process. You can create shells, insulating wraps, sand beds and ceramic cores. Automatic radiation view factor analysis fine tunes heat loss from the shell and maximizes simulation accuracy.

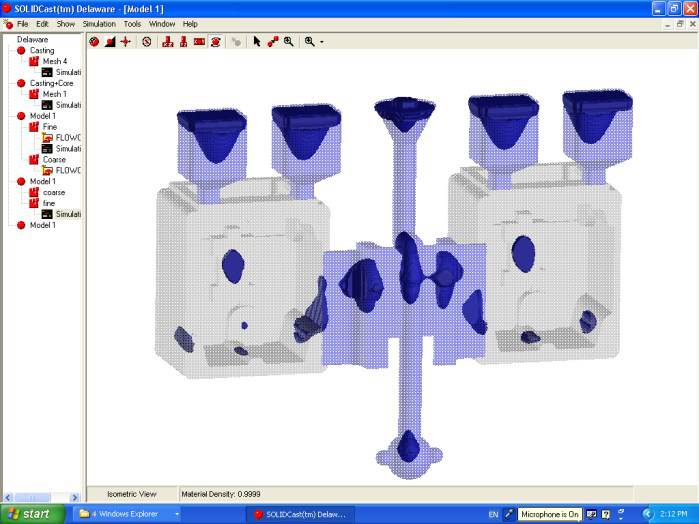

Permanent Mold Casting

SOLIDCast makes simulating the permanent mold process simple and efficient. Die heat-up is handled quickly and automatically. Insulating sprays and air gap formation are taken care of. Tilt-pouring realistically transfers metal from the pouring cup to the die as the die rotates.